The EU requires the electronics industry to achieve the ambitious goals of the EU Green Deal, Circular Economy Action Plan, and Industrial Strategy for the reduction of energy and material consumption, and utilization of circular value chains.

Sustronics project is targeting to improve the capabilities of the European electronics industry to meet these goals and develop new business opportunities from sustainable and greener electronics combined with an increase in productivity and new functionalities. The current electronic industry poses significant environmental impacts, such as increasing amount of e-waste, great demand for critical raw materials, and high energy consumption during manufacturing. The electronics industry can specifically decrease its environmental burden by shifting from fossil-based materials to bio-based materials, decreasing the use of metals, utilizing additive manufacturing processes, and developing miniaturized and integrated components, but also in broader scope by utilizing efficient circular economy business models that enable reuse, recycle and repair of critical materials and components.

Sustronics main goal is to support the renewal of the European electronics industry towards a circular economy, eco-design, bio-based materials, and material- and energy-efficient manufacturing processes. Thereby, Sustronics is redesigning electronics products into circular, compostable, and reusable products, and demonstrating that there are business opportunities in sustainable electronics.

Quantification of environmental impact, the definition of business models, involvement of external stakeholders, and means to guarantee compatibility with policies and standards is guiding the project implementation. The pilots are focused on healthcare, diagnostics, and industrial sectors, including topics such as medical and personal health devices, single-use and wearable diagnostics, sustainable lighting solutions, and embedded electronics for automotive.

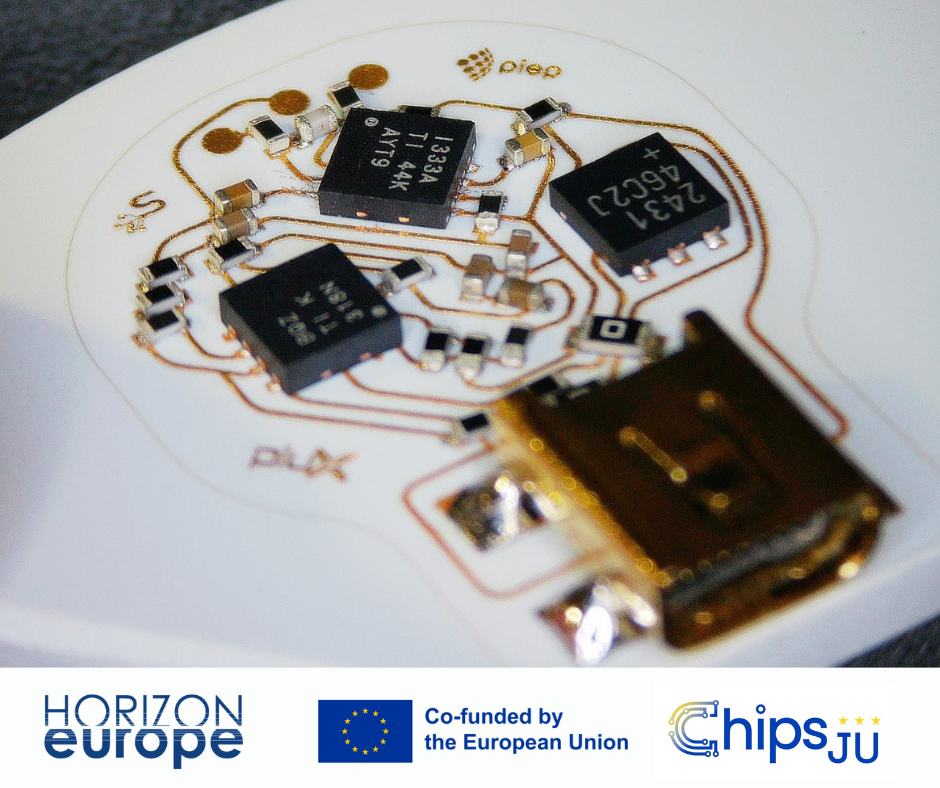

PIEP, and its partner PLUX, are developing a sensor for signal acquisition from Electroencephalography (EEG) using Laser Direct Technology (LDS). This 3D-MID technology allows a reduction in the number of components and product size. Materials with the incorporation of 50% recycled material are used for additive manufacturing of the prototype, and electronic components are soldered with decreased temperatures, contributing to a more sustainable product. The current prototype has 40% less environmental impact compared to the baseline.