The incorporation of electronics into plastic components has become a growing trend, and manufacturers are increasingly seeking to replace traditional complex buttons with functional substrates, incorporating them directly into the injection molding process. This technology, called In-Mold Electronics, or IME, involves printing patterns onto a polymeric substrate and allows not only to simplify products in terms of weight and multi-material design, but also their functionality, enabling the integration of components such as sensors or LEDs.

Applying IME to a polymer-based product enables the creation of lighter, more flexible, and more integrated electronic devices, as the circuits and components become part of the product’s structure, eliminating the need for additional parts. This new approach offers significant benefits in terms of performance and aesthetics, as well as more attractive product features.

Digital control during the transportation of goods through the monitoring and management of assets throughout the supply chain includes the use of GPS tracking systems, temperature and humidity sensors, wireless communication devices, or software platforms for real-time data collection and analysis. This methodology allows companies to track the progress of goods from their point of origin to their final destination, enabling a quick and effective response to mitigate issues such as delays or route deviations, or product storage conditions [1].

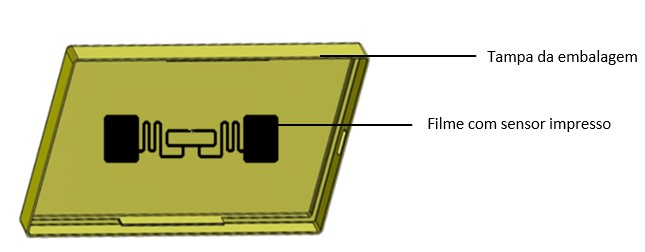

In this sense, the MEASURE – humidity sensor passive UHF RFID system, to be framed within the context of the ILLIANCE Agenda, emerges as a response to the development of solutions that combine printed electronics and plastic components. The solution consists of functionalized films with capacitive sensors to identify the relative humidity level inside a package and a UHF antenna for communication with a centralized monitoring system.

Figure 1 – Integration of IME into the overmolding process for prototype production (concept illustration)

The use of radio frequency identification (RFID) systems constitutes a viable alternative for inventory control and management, ensuring the security of packaged products. Unlike conventional methods such as barcodes, which require a direct visual reading of each product, this type of scanning uses tags, labels, or microchips that are activated by radio waves and contain relevant information about the product, such as the date of manufacture, location, etc. [2]. RFID systems thus allow for the automation of inventory records, as readers can simultaneously read multiple tags, supporting producers in their decision-making, whether in terms of replenishing stock or improving the quality of stored products through the inclusion of sensors.

Thus, the development of a sensorized storage box designed to track the contents of packaged products and measure their humidity levels adds value to freight transport products, particularly in terms of monitoring and controlling storage conditions, from the moment they leave the manufacturer, through distribution and marketing, to their use by the end consumer. These conditions are essential for reconstructing packaging history throughout the supply chain, enabling the detection of failure modes and the corresponding corrective actions to ensure the product is properly preserved throughout its life cycle. Thus, this type of solution aims to reinforce the product supplier’s quality assurance and implement a safeguard mechanism for the customer or end user, reducing the harmful effects of a non-compliant product.

Autorship:

Catarina I. Faria, Daniel Silva, and Sílvia Cruz (PIEP – Centre for Innovation in Polymer Engineering)

Pelin Gören e Filipe Cardoso (CS Plastic)

Article originally published in Molde Magazine.

References

[1] RFID na cadeia de abastecimento: vantagens | Artigos | Portugal Exporta. (s.d.). Portugal Exporta | Exportação e Expansão Internacional da sua Empresa. https://www.portugalexporta.pt/

noticias/rfid-na-cadeia-abastecimento

[2] Rao, K. V. S., Nikitin, P. V., & Lam, S. F. (2005). Antenna design for UHF RFID tags: A review and a practical application. In IEEE Transactions on Antennas and Propagation (Vol. 53, Issue 12, pp.3870–3876). https://doi.org/10.1109/TAP.2005.859919

ACKNOWLEDGMENTS

This study was carried out within the scope of the “Agenda ILLIANCE” Project [C644919832-00000035 | Project No. 46], funded by the PRR – Recovery and Resilience Program, within the scope of the Next Generation EU of the European Union.