During a kick-off meeting in Guimarães and Braga, CERN and PIEP launched a collaboration to develop non-flammable, sustainable and affordable thermal insulation for the Einstein Telescope, Europe’s next-generation gravitational-wave observatory.

Gravitational waves—tiny ripples in spacetime—were first detected in 2015 from the merger of two black holes. Since then, hundreds of cosmic events have been observed by today’s detectors, LIGO in the USA and Virgo in Europe. The Einstein Telescope (ET), now under design, will push this frontier further: with up to ten times better sensitivity than current observatories and the ability to probe signals below 10 Hz, it will explore a volume of the Universe at least a thousand times larger than today. This leap in sensitivity will open the way to detecting new astrophysical phenomena and possibly primordial gravitational waves from the dawn of the Universe.

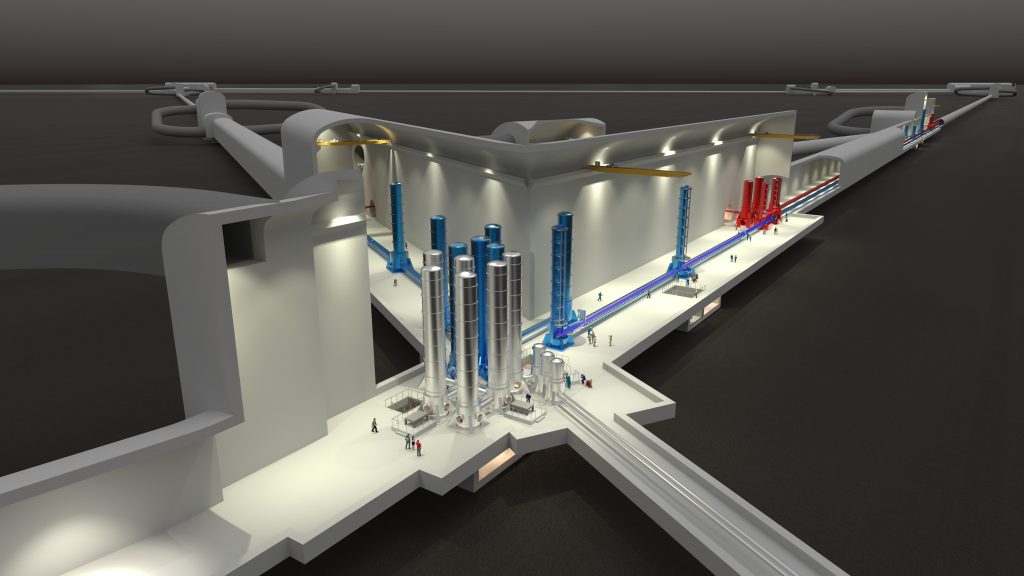

CERN is contributing to the design of ET’s ultra-high vacuum system, a 120-kilometre, 1-metre-diameter tubes where laser beams travel between mirrors. To achieve the required pressure below 10⁻¹⁰ mbar—ten trillion times lower than atmospheric pressure—the tubes must undergo a process called bakeout: heating above 100 °C for several days to remove residual water molecules.

To limit energy and temperature consumption in the underground tunnels, the vacuum tubes will require effective thermal insulation. This is where PIEP’s expertise is key. The Portuguese institute has proposed a dual approach based on tailored thermoplastic foams and a cork-based composite material, combining cork particles with tailored polymers, offering fire resistance, thermal insulation, and low dust emission. During the kick-off meeting, CERN teams visited PIEP’s facilities, Amorim Cork Solutions—one of the world’s leading cork producers—and the Polymer Engineering Department of the University of Minho.

This project reinforces Portugal’s role at the forefront of European scientific innovation.