The current global crisis, as a result of the Covid-19 pandemic, makes it essential to adapt existing industrial technologies to the development of innovative solutions that can serve as emerging technologies in a fight against two fronts, either at the level of an immediate targeted response to the SARS-CoV-2 virus or in terms of preparation and anticipation of future equivalent problems.

This Covid-19 pandemic was above all a reminder that there are, over practically the entire Earth, invisible biological agents, whether viruses or bacteria, that cause disease. It also came to reinforce the need and growing demand for materials, components, personal protective equipment, and medical devices that promote an improved barrier effect, for the end-user, against infectious and microbial agents.

InovPNT project aims to boost the production of functional and modified thermoplastic materials needed in healthcare

As plastics (additive polymers) have been widely used materials since the 1930s, with a growing trend in this use, the incorporation of biocidal agents on top of them can be considered a long-term practice. The viability of some polymers is due to their characteristics associated with their high molecular weight, design, and application flexibility, associated with a reduced raw material cost.

PIEP, together with CITEVE, and a TrimNW, presents the InovPNT project as a strategy that will serve as a proof of concept for the validation of an innovative solution that can be used in the future development of new products, aimed at personal protection equipment (PPE) and/or medical devices, capable of immediate response to the current pandemic. Through a concept validation, it will boost the use of functional and modified thermoplastic materials in the development of textile substrates with improved antimicrobial and permeability properties, through polymeric materials processing technologies, combined with non-woven fabrics (TNTs) processing techniques.

For this purpose, polymeric formulations were developed that include functional agents and/or antimicrobial nanomaterials compatible with the defined polymeric matrix (LDPE) and that allows the development of a TNT.

Figure 1. Example of some prototypes (EPIs) for the healthcare area with the incorporation of a silver-based additive in LDPE, applied over a non-woven fabric (TNT) as an antibacterial coating.

Among the most common functional antibacterial and antimicrobial agents, one of the most efficient and traditionally used in polymers is silver-based. These are relatively easy to incorporate, as it is a thermally resistant material. In addition to silver, other materials that can exhibit this type of antibacterial behavior are metal oxides, such as copper oxide. In general, microorganisms exposed to these materials lose their cellular integrity, suffer breaks in intercellular levels of ATP, and in the case of copper oxides, they can damage DNA and trigger oxidative processes that are harmful to these living beings.

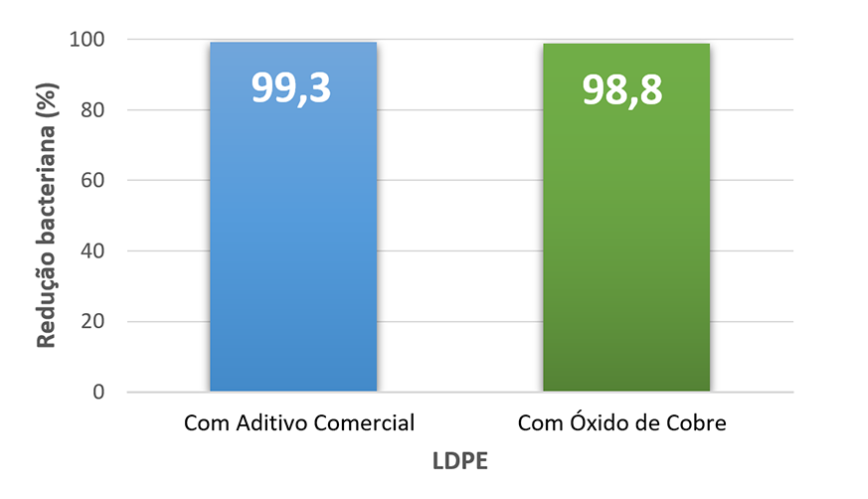

PIEP thus carried out the incorporation of copper oxide into an LDPE, which was then micronized and applied to a non-woven fabric (TNT) as an antibacterial coating in TrimNW. For comparison, a commercial additive based on silver was also incorporated, in order to have a positive control. In general, only values higher than 90% are considered as antimicrobials, and, preferably, values as close to 100% as possible.

Figure 2. Antibacterial determination (ASTM 2149) of TNT samples.

The results obtained with a culture of S. aureus bacteria demonstrate a very high antibacterial activity by the copper oxide used and are comparable to the silver base additive.

After the TNT samples were antibacterially validated, some prototypes were developed to demonstrate the developed technology, such as gowns and shoe covers (PPE) aimed at the health area. These also comply with EN 13795-1:2019 (Surgical clothing and drapes. Requirements and test methods. Surgical drapes and gowns).

Authors:

Miguel Guerreiro, Polymer Engineer, and Researcher at PIEP

Ana Costa, Project Manager of the Extrusion, Compounding and Advanced Materials area of PIEP

Article originally published at InterPLAST Magazine.

Find out more about the Extrusion, Compounding, and Advanced Materials area of PIEP.