The overall aim of the VITAL European project is to develop innovative processing solutions for microcellular foams from bio-based Thermoplastics (b-bTPs) and bio-based chemical blowing agents (CBA).

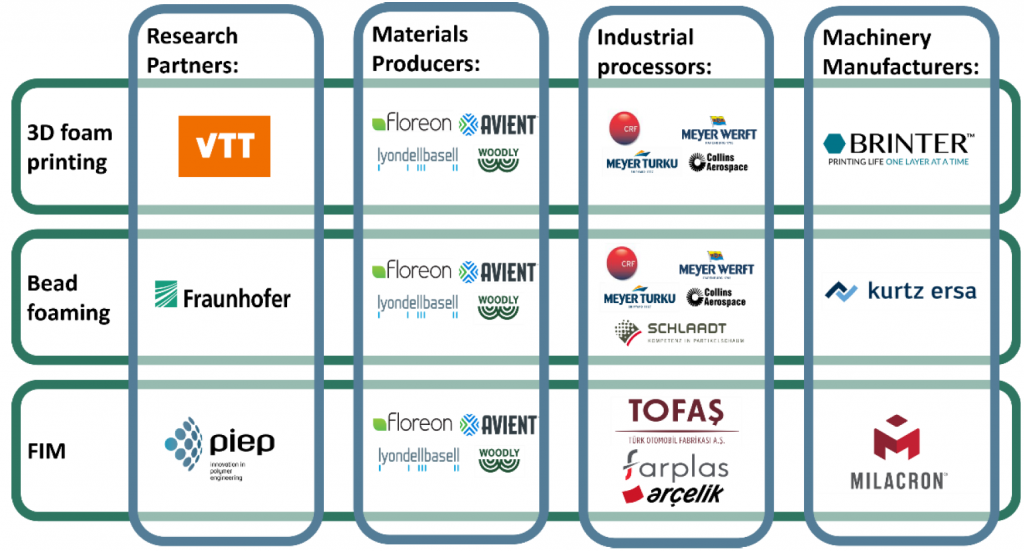

In this project three different value chains will be addressed:

For each of the considered technologies, case studies will be developed in order to assess the feasibility of the manufacturing process and evaluate the potential of the proposed solutions.

VITAL is a multidisciplinary project. Research, materials, machinery, and processing partners, for each value chain, are shown in Figure 1. This project is composed of 8 work packages (WP). PIEP is the lead partner in WP1 and WP4. Regarding WP1, PIEP will guide the end-users in defining the materials, process specifications, and test plans for each value chain process.

Concerning WP4, PIEP will focus on evaluating the feasibility of producing demonstrator prototypes using FIM technology through chemical and physical expanding agents, MuCell®.

In order to predict the size and distribution of the part’s morphology, FIM simulation will be performed by Moldex3D. Furthermore, it will be possible to predict the influence of the processing conditions on the growth of the cellular structure.

During the experimental work, a mould with a sapphire window set out with a high-speed camera and a microscopic lens will collect images during the process allowing an accurate capture of the foaming behavior and cell structure evolution. Thus, it will be possible to analyze the cell nucleation and growth in the part during the injection process.

Here, the integration of monitoring and control systems of the production process is also considered based on the incorporation of intelligence and sensing (pressure, temperature, and viscosity) of the production tool. Thereby, this type of system will allow analyzing the influence of real process conditions, thus, promoting the reproducibility of the produced parts.

The project also includes the study of the final mechanical performance of the different demonstrators, since the cellular structure will have an impact on the final mechanical properties of the parts. This work will be performed using Abaqus software that will allow a finite element analysis to evaluate the mechanical behavior of the demonstrators under service conditions.

The characterization of the developed materials will be the responsibility of PIEP, allowing the creation of a globally exclusive database of foamed b-bTPs that will feed commercial software considered in the study, either in the constitutive modeling of these materials, through numerical models of prediction of properties, as in predicting properties for conditions not analyzed experimentally.

In addition, VITAL will achieve the development of a commercially viable closed loop, mechanical recycling taking into consideration the specific requirements for b-bTPs.

Finally, the knowledge generated throughout the project in each value chain will be transferred through a professional training program – VITAL Learning Factory. Then, PIEP, being the lead partner in WP4, through this training action, will promote the transfer of know-how regarding the adoption of processing solutions developed for foamed b-bTPs, thus promoting a paradigm shift towards bio-based alternatives.

Image: Consortium partners by value chain.

This project will be developed under the support of the program Horizon Europe Framework Programme (HORIZON) (Call: TWIN GREEN AND DIGITAL TRANSITION 2021; ID: HORIZON-CL4-2021-TWIN-TRANSITION-01-05: Manufacturing technologies for bio-based materials).