Plastics are inexpensive, lightweight, and durable materials, which can readily be processed into a variety of products that find use in a wide range of applications.

These great advantages have determined the increase of their use during the last 60 years. However, the high levels of usage and disposal have generated several environmental problems.

Considering that 4% of the world’s oil and gas production is used as feedstock for plastics and an additional 3-4% are used to provide energy for its manufacture, and most of this plastic is used for short-lived disposable products, one can infer that the current use of this material is not sustainable.

In addition, because of the durability of the polymers, large quantities of discarded end-of-life plastics are accumulating as debris in landfills and in natural habitats worldwide [1]. For instance, Europe produces 60 million tonnes of plastic every year, but worryingly only around 30 percent of this is eventually recycled [2].

This evolution has been coupled with consumer perceptions and brand owners’ understanding of the recoverability and circularity of products. A 2018 Deloitte survey found two-thirds

of shoppers are willing to pay extra for sustainable products. Brand owners such as PepsiCo have made public commitments to circular visions of their plastic use (“to build a world where plastics need never become waste”) [3]. And last, but not least, legislative policies have been put into place to accelerate plastic reuse and recycling while focusing on designs and solutions that reduce the amount required per part.

To this end, new disruptive technologies and strategies have to be developed allowing the industry to reach its full potential with a renewable, efficient, and durable raw material.

The brave new world of disruptive technologies

According to Bower and Christensen, disruptive technologies introduce a very different package of attributes from the one mainstream customers historically value, and they often perform far worse along one or two dimensions that are particularly important to those customers. As a rule, mainstream customers are unwilling to use a disruptive product in applications they know and understand [4].

One of these innovations was developed by a team of researchers at the U.S. Department of Energy’s (DOE) Lawrence Berkeley National Laboratory (Berkeley Lab). They designed a recyclable plastic that can be disassembled into its constituent parts at the molecular level and then reassembled into a different shape, texture, and color again and again without loss of performance or quality. The new material, called poly(diketoenamine), or PDK, was reported in the journal Nature Chemistry [5].

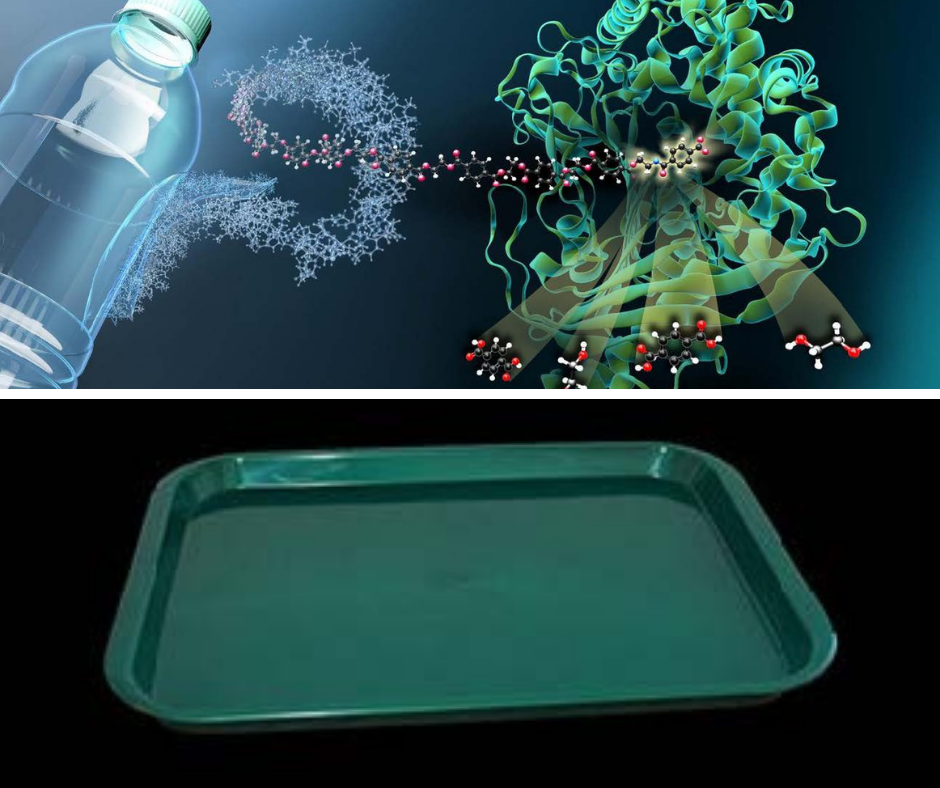

Equally impressive is the emergence of biodegradable plastics. Most synthetic plastics are not biodegradable but, according to Syranidou et al, “a wide range of organisms can settle on the weathered surface” of plastic debris, which they use “as a substrate and as a carbon source”. And these strains of bacteria could potentially speed up the plastic degradation process [6]. The plastic mix contained Polyethelene which is widely used to make plastic carrier bags and polystyrene, which is commonly found in food packaging and electronics. After five months of weathering the plastics with the bacteria, a reduction of plastic mass of up to 11 percent was achieved.

Figure 1: ocean-plastic-made foodservice trays with bacteria-resisting protection

Naturally, as stated by Bower and Christensen, the great obstacle is to ensure the buy-in of mainstream customers who are unwilling to pay more for a commodity. However, as COVID-19 has clearly shown, citizens will quickly adapt to new circumstances if the context is right and if the governments lead the way in enforcing legislation.

On that subject, disruptive innovation on relatable items might make sense if the circumstances change abruptly. One of these examples is the development of technology that makes polymers resistant to bacteria, molds, and biofilm. Inspired by human skin and its protection against germs and viruses, polymers with integrated zinc have a 99.9% or higher antimicrobial performance [7].

This new material/concept was developed by Parx Materials, a start-up created in 2014 from Rotterdam, The Netherlands. Inspired by the defense mechanism of the human skin and its protection against germs and viruses through the use of zinc, Parx Materials is integrating this metal into polymers to obtain a 99.9% or higher antimicrobial performance. Independent tests using ISO 21702 protocol for the Human Corona E229 virus proved that the Parx Materials technology reduces the lifetime of the virus five times faster than when compared to normal solid plastic surfaces.

Disruptive innovation based on thermoplastics also addresses the energy, automotive, and aeronautic sectors. For the wind energy sector, thermoplastic shields for blades, known as armourEDGE, are being considered to protect the leading edge of wind blades [8]. Advancements in this sector could lead the way to a renewable energy source-based economy.

Figure 2: armouredge leading edge protection solutions

Thermoplastic composites are also prime candidates for the aircraft of the future. Highly efficient means of transport completely built with renewable materials are a feasible endeavor.

All these applications take into account the admirable properties of thermoplastics while taking advantage of their recyclability capabilities when compared to other alternatives. If this material achieves its renewable potential, the companies that stand behind the innovation that led the way to this goal will be in a prime position to lead their respective industries into the next century.

Author: Pedro Mimoso, Business Developer Director at PIEP

[1] J. Hopewell and R. Dvorak, Plastics recycling: challenges and opportunities. The Royal Society Publishing, 2009.

[2] M. Campbell, Discovery of plastic-eating bacteria marks breakthrough for scientists. Euronews, 2020.

[3] P. Krieger, Renewable and recyclable? Recycling today, 2019.

[4] JL., Bower and C.M. Christensen, Disruptive Technologies. Harvard Business Review, 1995.

[5] S. Snowden, Scientists create a plastic that can be recycled indefinitely. Forbes, 2019.

[6] E. Syranidou et al, Biodegradation of mixture of plastic films by tailored marine consortia, Journal of Hazardous Materials, 2019.

[7] R. Lingle, Zinc highly effective against viruses on plastic surfaces. Plastics today, 2019.

[8] R. Herring, K. Dyer, F. Martin and C. Ward, The increasing importance of leading-edge erosion and a review of existing protection solutions. Renewable and Sustainable Energy Reviews, 2019.