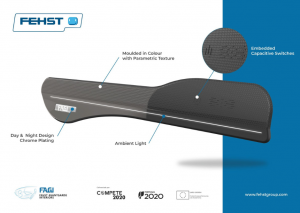

This project aims to create new technological solutions for the production of components, through the production process of injection moulding, that integrate the interior of a car. Here, with regard to the aesthetic part, the aim is to develop new solutions that allow the production of pieces with decorative surfaces not only with different design patterns but also different types of surface finish, without the need for additional finishing operations.

It is also intended to obtain selective chrome plating on components produced from the bi-material moulding production process. As for the functional part, it is intended not only the development of new solutions that allow obtaining tactile surfaces with feedback but also the incorporation of light guides, in order to achieve uniform illumination throughout the piece.

Thus, using cutting-edge technologies, and addressing issues of cost reduction and environmental impacts, this project aims to integrate these technologies into an innovative and demonstrative product: a frieze of an aesthetic and functional door.

More on this project:

Download project sheet.