Automotive

HC2W

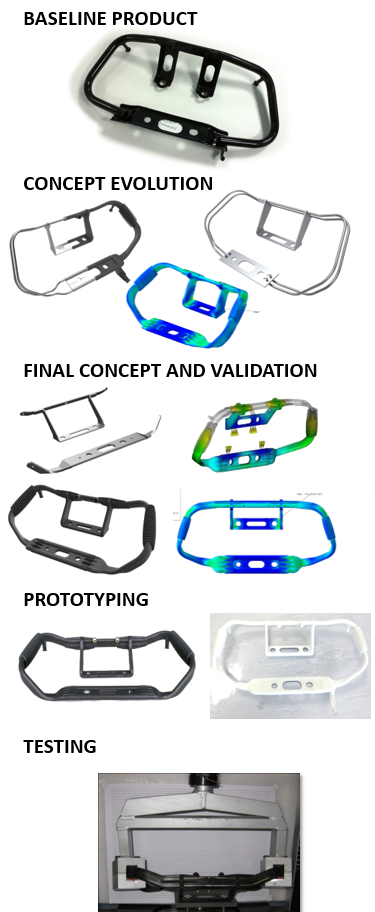

Development of motor vehicle components through the use of hybrid solutions, with:

– 35% weight reduction in four components: rear handle, speed pedal, brake rod, and headlight support;

– Increased resistance to corrosion (reliability and durability);

– Elimination of the use of polluting metals in obtaining components of visual aspect;

– Unification of functions.

The studies focused on the selection of materials, the optimized definition of molding geometries, and the proper establishment of processing conditions.

Components with high mechanical performance, improved visual appearance, and integrated functions have been achieved, also obtaining a substantial reduction in assembly and finishing tasks of the components.