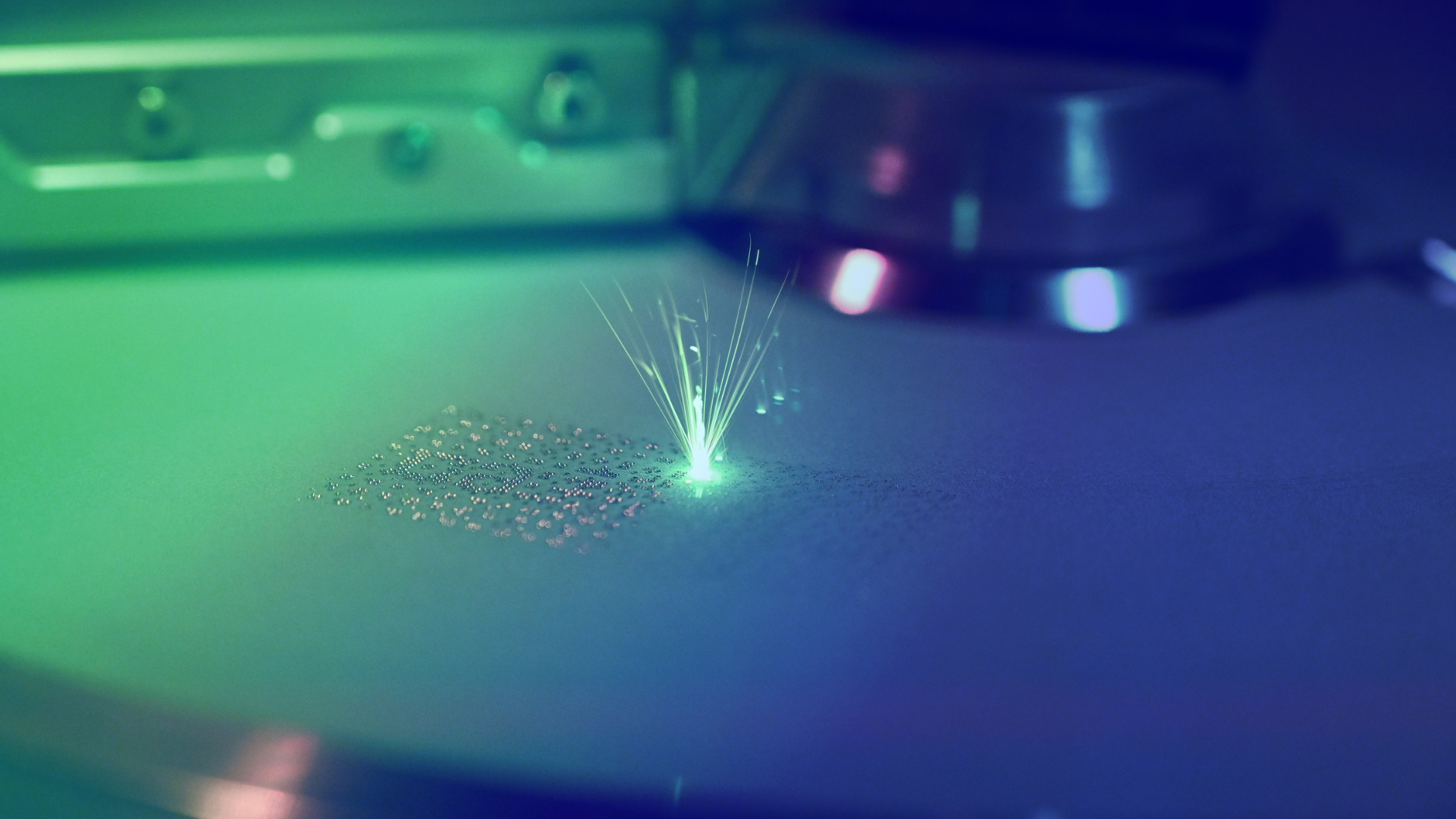

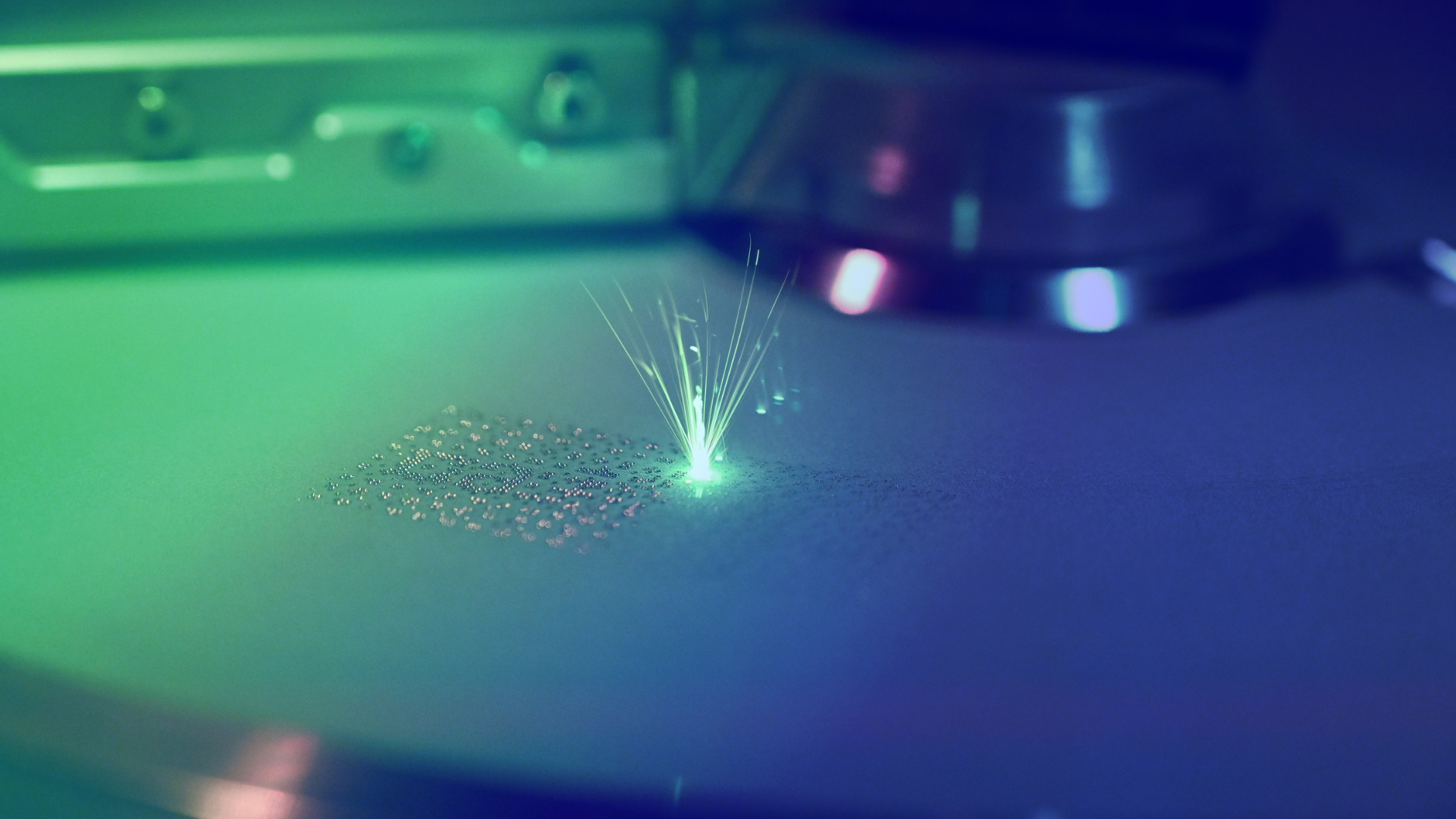

INOV.AM is a program that mobilizes Innovation in Additive Manufacturing from the Mobilizing Agendas for Business Innovation that aims at the development of new materials, advanced manufacturing processes, advanced post-production processes, advanced automation and control software, new products, and training and qualification of human resources.

Objectives

The project aims to combine additive manufacturing technologies with the injection moulding process, in a single and innovative production cell, so that hybridisation occurs. Through this technological combination, it will be possible to improve the efficiency, simplicity, associated cost, and sustainability of the production processes, as well as ensure the quick customisation of products obtained for various industries, such as, for example, the automotive and food sectors.

The aim of the project is to create a productive tool, obtained by combining different technologies and materials, with the aim of obtaining polymeric parts for everyday use. This tool is called a hybrid mould, since it consists of a conventional structure and moulding inserts produced by combining traditional materials and additive manufacturing, through conventional technologies and additive manufacturing. The hybrid mould can be used as a moulding tool, for example, in injection technologies, thermoforming, blow moulding, or others, for the production of small and medium series, as well as injected prototypes for validation of products or systems, before large-scale production.

In addition, it is intended to apply this technology and construction material to create polymeric and metallic components to integrate leisure and competition sports equipment, replacing current components. To this end, digital tools will be applied to optimize the mass and maximize performance, thus ensuring the efficiency of the structural capacity of the part simultaneously with the lightness of the solution. These components will be produced by additive manufacturing with metal and polymers, as building materials, and can be directly applied to products or have an additional step of over-injection, thus obtaining a hybrid product with a plastic coating for finishing or adding comfort. touch, among other possible functions.

PIEP is working on the Work Packages for the project:

Download project sheet.