The plastics industry for the automotive sector has continuously sought to develop new technological solutions, with greater added value, based on the optimization of products and processes together with the reduction of weight and the number of components and for these reasons invested in innovative technology, strict quality control, as well as the elimination of manufacturing steps.

Hybrid injection moulding technology presents itself as an approach capable of producing very complex multi-component products in a single step and in a unified product. This technology has been increasingly used to replace conventional injection moulding technology, for situations where there is a need to group together in a single component different materials with different properties, making the production process more efficient and reliable, thus reducing industrial costs. In fact, this technology gives more freedom to combine, in particular, different mechanical properties, an essential factor in the design of a multi-functional part, increasing the part’s qualities of rigidity and elasticity.

This technology has been widely used in the production of polymer-metal hybrid parts. Thus, in Hybridplás, an R&TD project, with a consortium between PIEP – Centre for Innovation in Polymer Engineering, Safiplás – Injeção de Plásticos Lda, and the University of Minho, hybrid solutions used in the automotive industry are being obtained.

This development is centered on two innovation vectors: solutions for the over-moulding of metallic elements and conventional/unconventional technologies of injection moulding for glass elements with plastic for technical parts of reduced dimensions and with dimensional tolerances of the order of +/- 0.05mm, in large production series.

In this project, two different case studies are developed, a Polymer–Metal hybrid product and a Polymer–Glass hybrid product. According to the project objectives, it is intended to reduce the number of components to be assembled, as well as the number of stages of the production process in question, obtaining a highly integrative and high-performance product according to the imposed requirements.

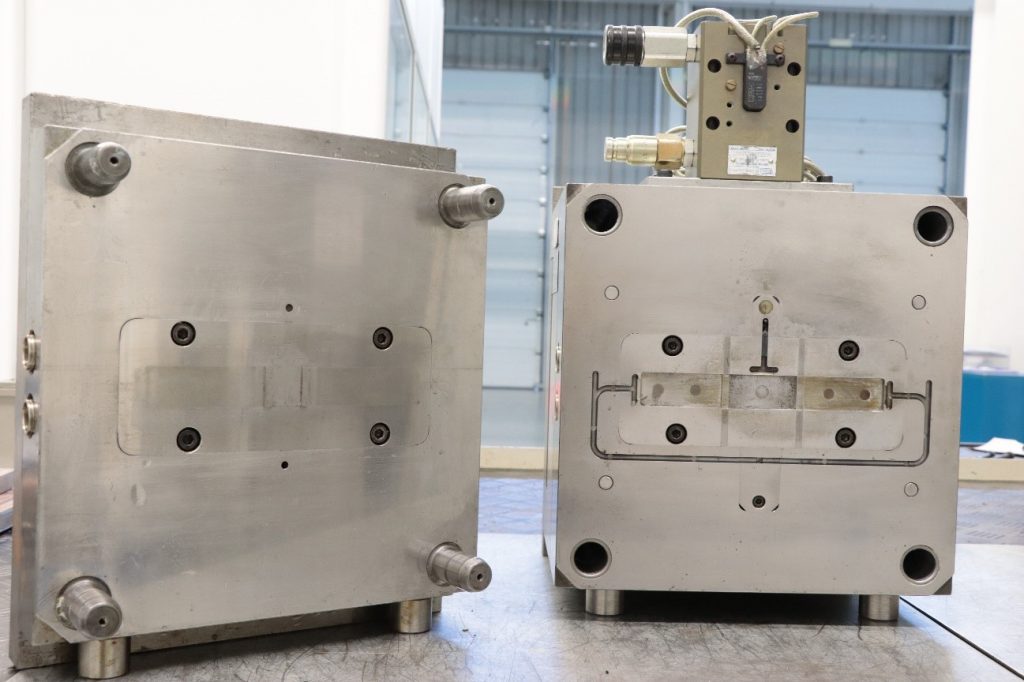

Figure 1. Open mold overview: extraction side (left) and injection side (right).

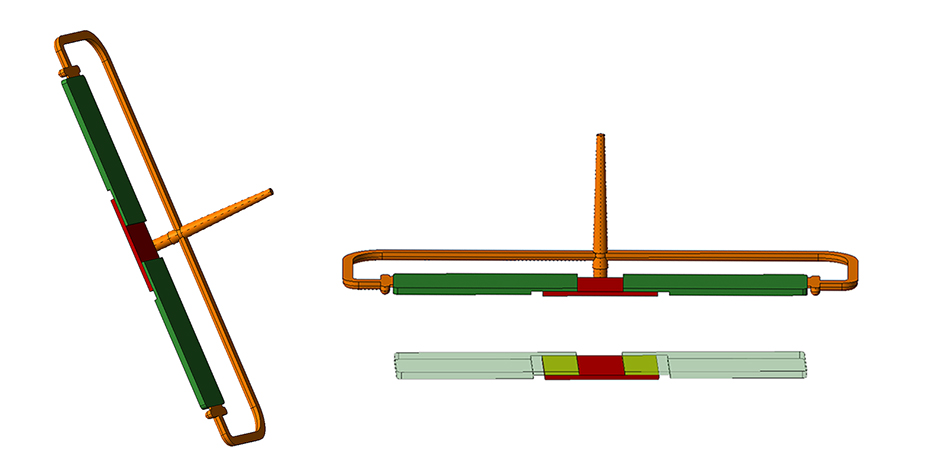

To better evaluate the effect of the interface between the polymer and the insert to be used, a mould was prepared that allows adaptation to a large number of materials, both for the insert and for the polymer. The polymer is injected directly onto the metallic or glass insert, previously placed in the mold (Figure 1), thus forming a single piece, without the need for post-moulding operations. In this study, the parts to be injected are made of two materials, as shown in Figure 2, with the red designating the insert and the green representing the polymer where it will be injected with the aid of the cold supply channels (orange) on the opposite sides of the sample.

Figure 2. The perspective of the hybrid part with the cold channels: Attack and the channels (orange) / metallic or glass insert (red) / Polymer (green) and polymer-insert adhesion interface (yellow area).

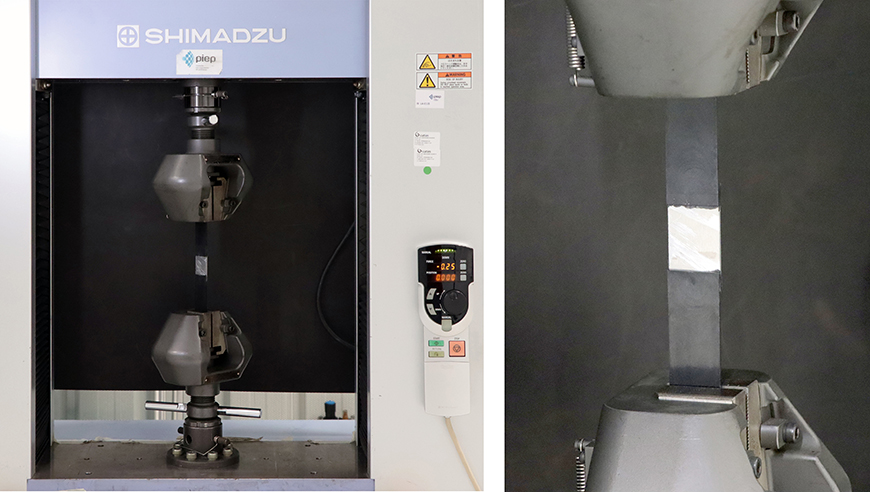

Through this process, several strategies are being studied to obtain greater adhesion between the two materials, eliminating another joining operation. This study has been evaluated using tensile tests (Figure 3), which provide us with an analysis of the quality of adhesion at the interface between materials.

Figura 3. Tensile tests

The result will be to obtain a better performance of the product, the production process, and the integration of functions in the final product, which will provide an overall cost reduction of the proposed solution according to what exists in the market.

Acknowledgment

Work carried out within the framework of the HybridPlás Project, (Proj.42954), financed by the European Regional Development Fund (ERDF) through the Operational Program PO North.

Author:

Clara Gonçalves, Researcher at PIEP – Centre for Innovation in Polymer Engineering

Article originally published in InterPLAST magazine.