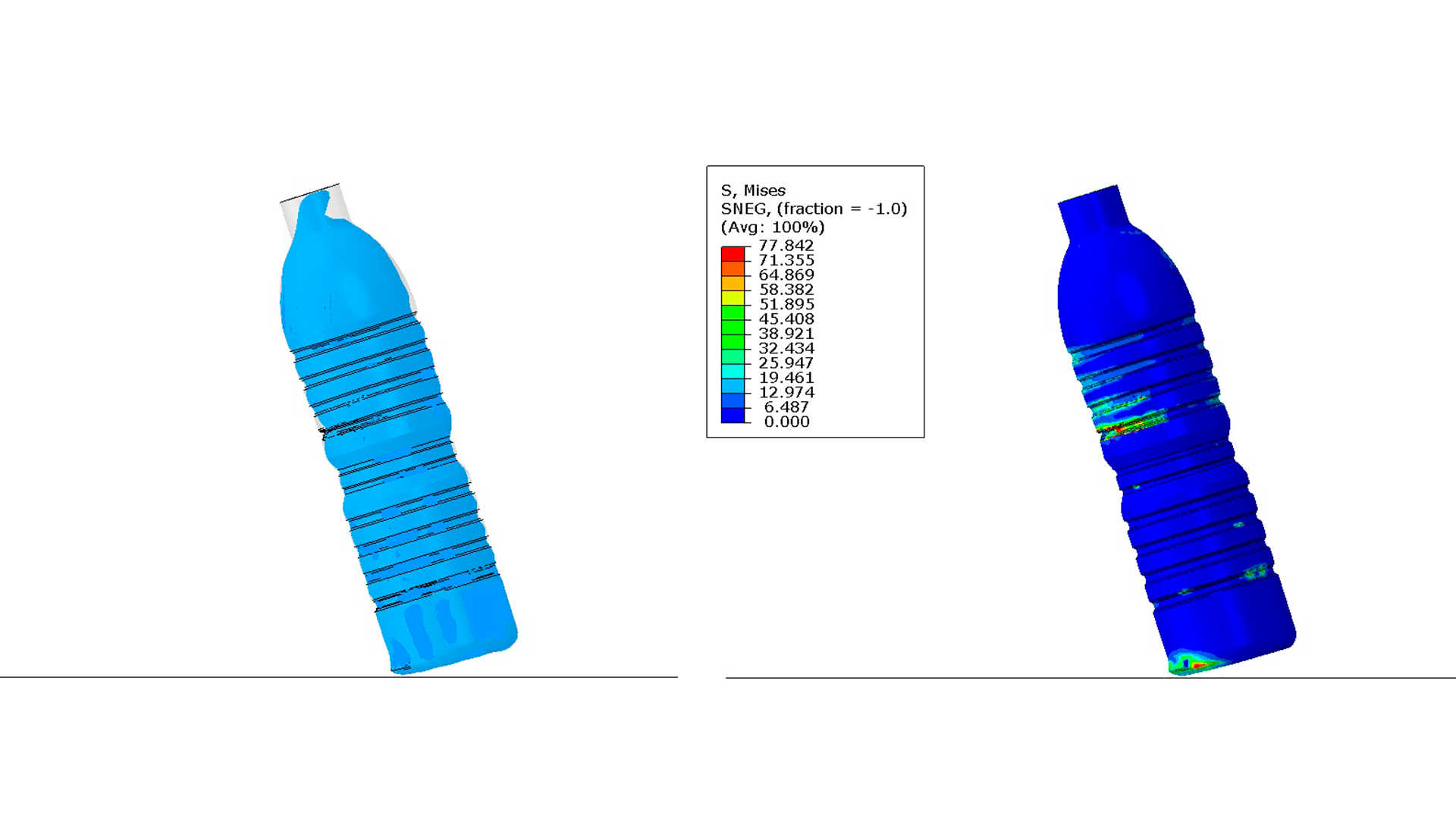

Image: Waterdrop test simulation with water

Traditionally, packaging design and production are based on trial and error processes and simple changes in material specifications or packaging geometry, making it difficult to achieve the desired level of effectiveness. This iterative process is time-consuming and expensive, seriously impairing the manufacturer’s ability to respond to rapidly changing market requirements.

Development of food packaging

The industry is increasingly focused on computational tools that can be incorporated in all stages of packaging development, from conception and design to correcting or improving the production process, or even in more advanced stages, as the manufacture and testing of the final product.

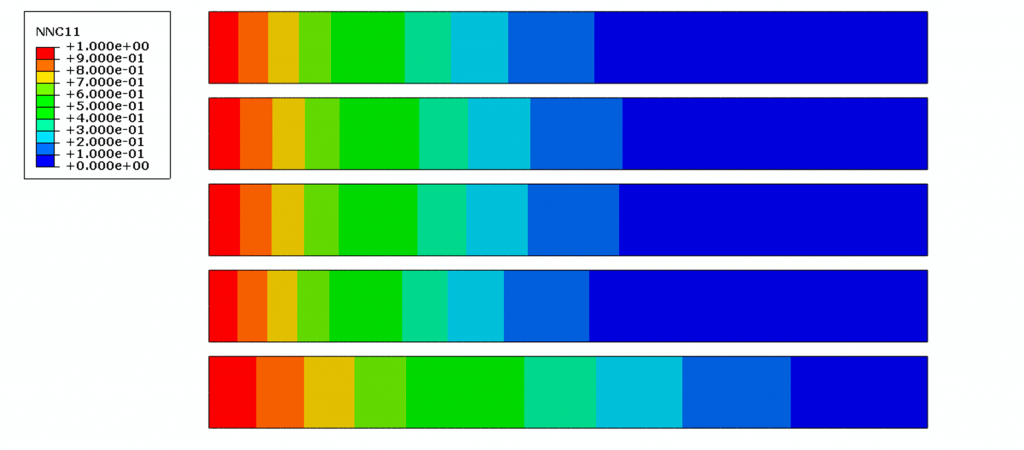

In the case of food packaging, correct development of the packaging maximizes its performance, including its protective properties against gases such as oxygen and water vapor, or other contaminants existing in nature, responsible for the deterioration of the food product. The implementation of numerical simulations in the initial stages of the development of packaging allows the early correction of any construction flaws and makes it possible to obtain a packaging with optimized shape, size, weight, and performance, meeting all the specifications imposed on the product in question and associated process.

Image: Simulation of gas permeability through multilayer films

Advantages of applying numerical simulations

One of the main functions of a package is to conserve its contents, aiming at preserving its quality and safety and, thus, prolonging its life span. The development of virtual prototypes makes it possible to evaluate and test the behavior of the packaging at different stages of its life cycle, such as drop, durability and fatigue tests, thermal and structural performance. The analysis of packages with water or other fluids inside is more complex since the fluid significantly influences its structural performance. Combining different methods, the FSI numerical simulation (Fluid-Structure Interaction) allows evaluating the structural integrity of the packaging with fluids, after a drop test or other mechanical effort. From this analysis, it is possible to optimize the thickness and design of the packaging, in order to meet the mechanical requirements.

In addition to the gains in the product development process and the optimization of its behavior, the use of numerical tools is also advantageous in the optimization of the production process. Manufacturing processes widely used in the packaging industry, such as thermoforming and blow molding, and the parts produced by them, often have defects such as heterogeneous thickness distribution, sheet stretching/distortion, fold formation, among others, which may compromise the behavior of the final product. The simulation of manufacturing processes appears as a solution for forecasting and timely correction of defects inherent to the production technique. It also allows the study of the influence of the process parameters on the final product for better optimization of the process and provides a forecast of the times associated with it, improving the production time.

PIEP uses numerical simulation in projects and services in the packaging area, in order to optimize its performance in the most diverse themes (permeability, structural and thermal) and optimize the conditions of the production process, achieving significant advantages: minimizing risks, reducing time and costs, and maximizing innovation. It facilitates the entire development process and allows to bridge the various construction flaws, avoiding complex experiments and tests on physical prototypes, reducing costs, and accelerating the process of launching the product to the market.

Authors:

Susana Costa – Polymer Engineer and Researcher

Filipa Carneiro – Product Design and Development area coordinator

Article originally published in InterPLAST Magazine March 2021.

Know more about R&D in the Product Design and Development area of PIEP.