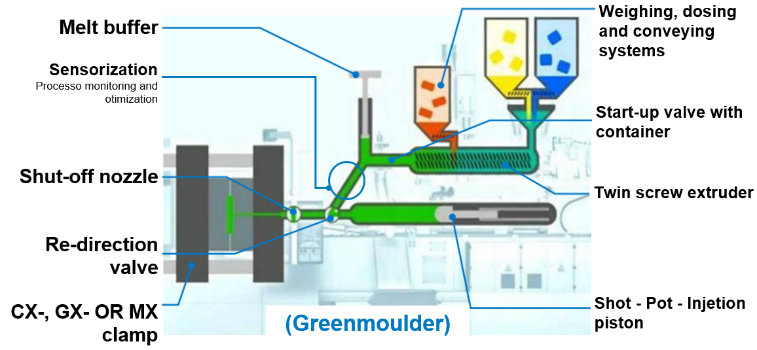

The Greenmoulder is a 230Ton Injection Moulding Compounder (IMC), a compounding and moulding equipment in a single process, developed by PIEP and Plasdan, which ensures the mixing of various components in a polymeric matrix and its subsequent injection. The integration of a contra-rotating twin-screw extruder allows cutting rates on materials to be reduced. It also has a degassing module, allowing the processing of materials in an inert environment, particularly advantageous for hygroscopic materials. As this concept replaces the conventional compounding step, it makes it particularly suitable for processing thermally sensitive thermoplastics, as well as recycled materials, by reducing the number of thermal cycles they are subjected to.

In addition, the combination of these two stages eliminates the need for granulating the material (pellets), whereby the length of the fibres is maintained in the integration of long fibres in the composition, thus making it possible to produce parts with superior mechanical properties. On the other hand, the combination of these steps leads to an increase in the energy efficiency of the process, which has positive implications in reducing the cost of producing parts.

In general, the IMC concept allows the development of new solutions for the reuse of materials, namely composites, and the application of natural materials and bio-polymers, reducing the possibility of thermal degradation, and maintaining the mechanical properties of the processed material. Currently, the growing trend towards the incorporation of recycled materials, such as, for example, long fibre composite materials, implies the need to adapt the material composition processes and the respective production processes, in order to guarantee the production of recycled components, with thermomechanical characteristics compatible with the expected service conditions.

In this way, the concept of IMC can be applied in the recycling of polymeric materials, reinforced with long fibres, resulting in a new solution for the recycling of composite materials, namely the constituent materials of continuous fibre composite laminates. In this sense, PIEP applied the IMC concept to the production of a part, by injection moulding, obtained by recycling a thermoplastic composite with a matrix of PMMA-Polymethylmethacrylate (ELIUM® 188XO) reinforced with continuous carbon fibres, initially produced through the technique of Vacuum Assisted Resin Infusion-VARI.

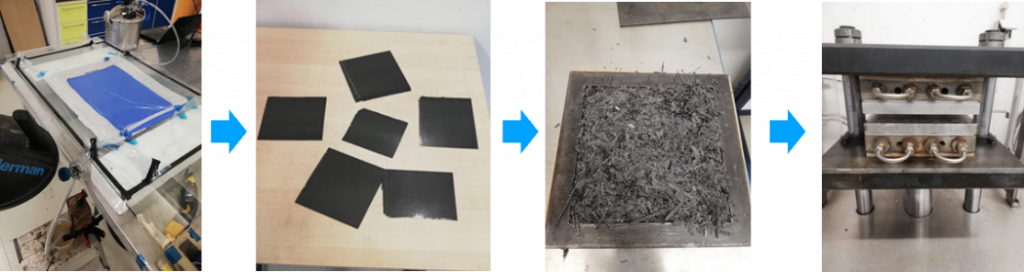

In Figure 1, the phases considered until obtaining composite plates, by hot compression moulding, necessary for the previous tests of mechanical and physical characterisation of the recycled composite material are schematically represented. The composite granulate, shown in Figure 1, underwent an additional layering process in order to allow the study of the dependence of the mechanical behavior of the material on the length of the fibre. From this process, granulates with three different granulometries were obtained, namely: <1mm, [1, 2.5] mm, and [2.5, 5] mm.

Figure 1 – Phases of the process for obtaining recycled composite material. From left to right: 1) Vacuum-assisted resin moulding process -VARI; 2) cutting of the composite board; 3) mechanical granulation; 4) hot compression moulding.

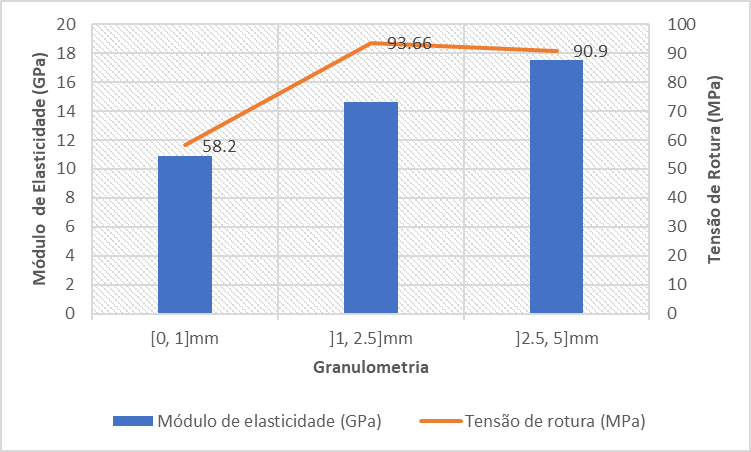

In Figure 2, a proportional relationship between the length of the fibre and the increase in the modulus of elasticity of the recycled composite is evident. This proportionality relationship is not so evident for the tensile strength, which seems to stabilize for granulometry values above [0.1] mm. Figure 2 shows, graphically, the variation in modulus of elasticity and breaking stress with granulometry. Observing the graph allows us to conclude that an increase in the length of the fibre corresponds to an increase in the stiffness of the material, translated by the corresponding increase in the modulus of elasticity. The breaking stress stabilizes, approximately, at 90MPa, not showing as much dependence with the increase of the fibre length, as evidenced by the values of the modulus of elasticity. In this regard, it would be interesting, given the reduced number of samples tested, to increase the sampling in order to better consolidate the conclusions regarding the evolution of the rupture stress.

Figure 2 – Comparison of the modulus of elasticity and tensile strength of the recycled composite material, considering the variation in fibre length (granulometry).

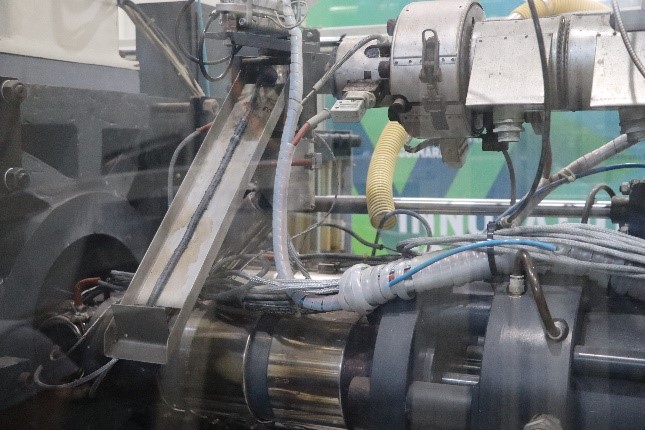

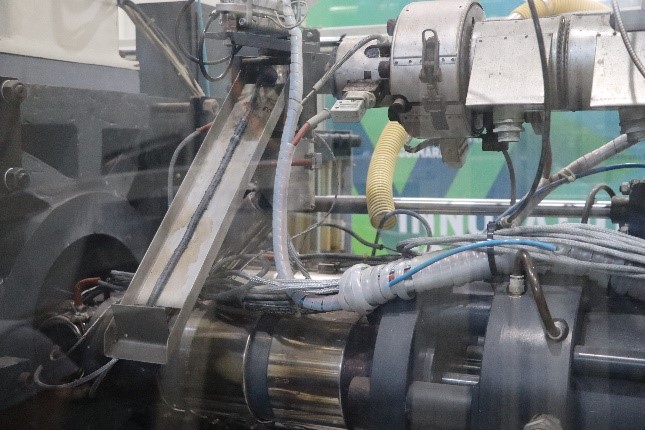

The recycled composite, after being properly characterized, was processed using the IMC technique. The injection and material compounding process in a single process (characteristic of the IMC process) is particularly suitable for processing thermoplastics with a high percentage of incorporation of long fibres. In fact, the IMC process eliminates the need for intermediate steps such as pelletizing the raw material; a step that reduces the length of the fibres; enabling the production of parts with better mechanical properties [1], being about 40% more energy efficient than the traditional extrusion compounding sequence, followed by injection [2]. In Figure 3, an overview of the IMC machine available in PIEP and a high-level diagram of the process is presented.

Figure 3 – General view of the IMC machine in a). In b) schematic representation of the IMC process.

Recycled composite material, produced during the sample production phase, was used for the injection moulding of a functional component. The material is compounded in the extruder unit and transferred to one of the injection cylinders where it is subsequently injected. In Figure 4 it is possible to observe the material resulting from the purge. The piece obtained has the configuration shown in Figure 5.

Figure 4 – Purging of the composite recycled material resulting from the composition phase by the IMC technique.

Figure 5 – Piece in recycled long fibre composite, obtained through the IMC moulding technique.

[1] M. G. Battisti and W. Friesenbichler, “Injection-Moulding Compounding of PP Polymer Nanocomposites,” Strojniški vestnik – Journal of Mechanical Engineering, vol. 59, no. 11, pp. 662–668, Nov. 2013, doi: 10.5545/sv-jme.2012.903.

[2] Bürkle, “Energy-Efficient Processing of Natural Fiber-Reinforced Plastics,” Kunststoffe, vol. 2, pp. 25–29, 2009.

Authors:

Paulo Antunes, Rafael Alves, Joana Malheiro, Cátia Araújo, Sílvia Cruz.