New technologies and materials as new opportunities for injection systems

In recent years, the mold and plastics industry has witnessed significant advances in injection systems, driven, for example, by the growing need for more controlled processes, lighter parts, and better properties.

Regarding technology, the growing use of 100% electric injection molding machines, which are more efficient and precise, stands out. Regarding the process, greater precision in injection speed and pressure, as well as mold positioning, enables the production of higher-quality parts with fewer defects. Furthermore, this evolution translates into less material waste and lower energy consumption, thus contributing to the reduction of CO2 emissions [1].

Currently, automation, using robots and other peripherals, is increasingly being applied to optimize processes, increasing their efficiency, precision, and consistency for part quality control through the identification of colors, visual defects, and dimensional defects. Additionally, remote process monitoring, which allows for remote control, has also been implemented in the plastics industry. However, although automation and digitalization are currently the main focuses, Industry 5.0 is essentially human-based and, therefore, aims to enhance, rather than replace, human capabilities, ensuring a balance between stakeholders [2]. Through human-machine collaboration, the industry seeks to strengthen human decision-making capabilities through predictive analysis, equipping them with advanced tools to improve thermoplastic part production and cycle reproducibility [3]. Traditional robots, often used for handling and moving parts, insert placement in molds, and assembly or packaging processes, have evolved due to industry demands. Therefore, the use of collaborative robots (cobots) has been increasingly introduced due to their lightness, versatility, and reduced cost, making them a viable alternative for lower-volume production. Thus, in addition to improving productivity, cobots, when programmed to interact with humans, also result in increased employee safety.

In the same context, the ability of new machines to measure and digitize various data in real time allows for more rigorous process control [4]. The implementation of sensors in the injection molding process ensures real-time control of material behavior in the mold by measuring cavity pressure and temperature, allowing for the adjustment of dynamic variables instantly in each cycle. By adjusting conditions in real time, in addition to implementing predictive maintenance that enables data collection and analysis throughout the value chain, it is also possible to optimize production cycles and anticipate failures or defects to minimize downtime.

Figure 1 – Foaming Injection Moulding unit

One of the key concepts of Industry 5.0 in the plastics production chain is the introduction of new, more sustainable, biodegradable, or compostable materials, as well as high-performance materials for the development of more durable and lighter products. Across the board, companies have made evident their efforts to utilize recycled materials, both post-consumer and closed-loop, through the recovery of material from the process (purges, setup, etc.). These materials are then combined with the application of advanced injection technologies to overcome process, design, or material limitations in the production of increasingly complex products with more stringent requirements, exceeding the expectations of an increasingly demanding market while minimizing the environmental impact of their processes and products. The introduction of solutions that go beyond the state-of-the-art dictates the market positioning of companies in the national industry and enhances their position in the global market, contributing to competitiveness and internationalization [5]. Thus, the injection systems paradigm has been enriched by new trends, notably the use of technologies such as gas- or water-assisted injection, which aim to reduce raw material consumption and improve the weight-to-strength ratio of the parts produced. This process involves introducing an inert gas (usually N2) or water into the molten polymer to create internal cavities during the injection molding cycle, resulting in the production of hollow parts with optimized material distribution and reduced shrinkage and warpage [6].

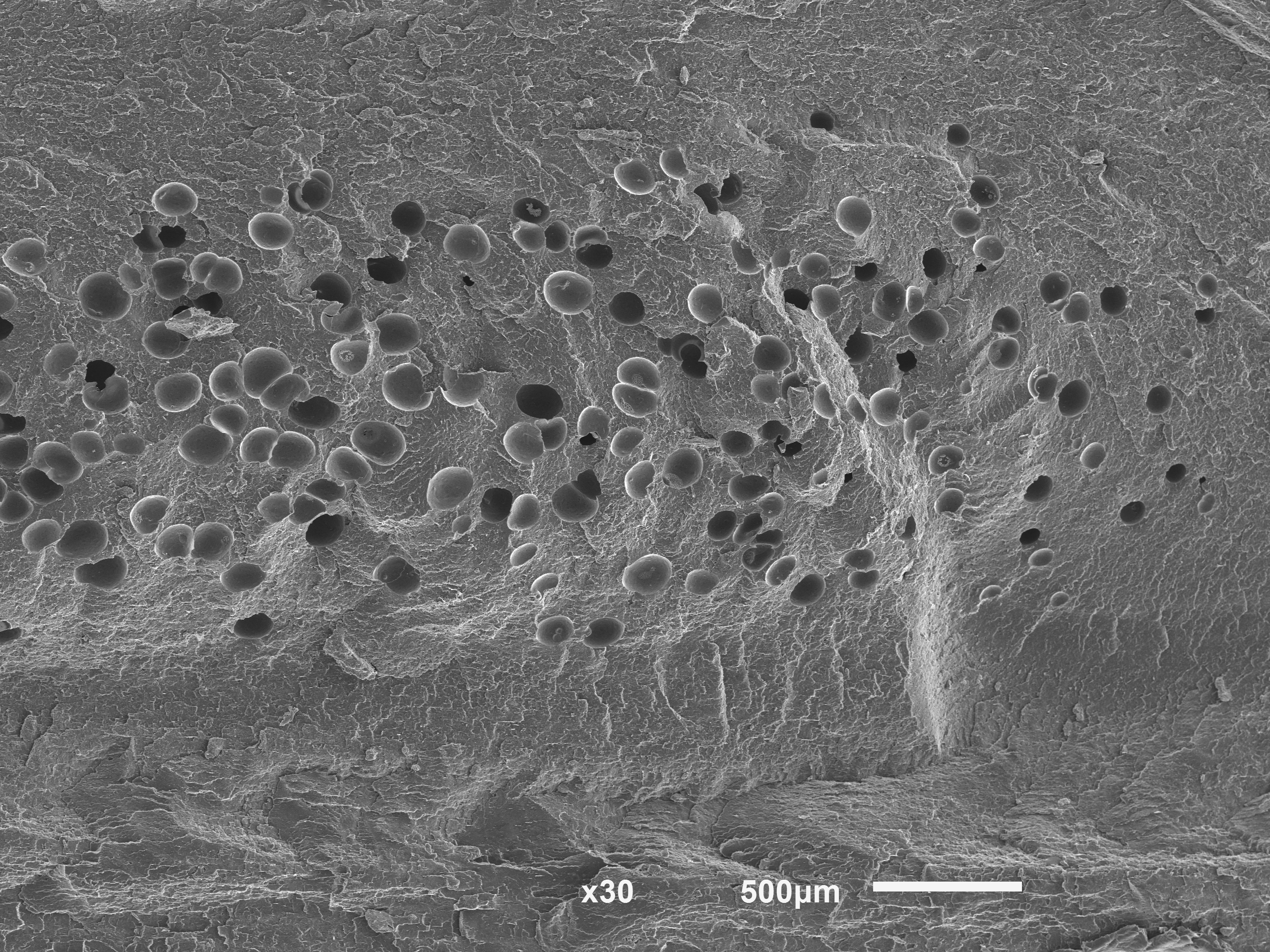

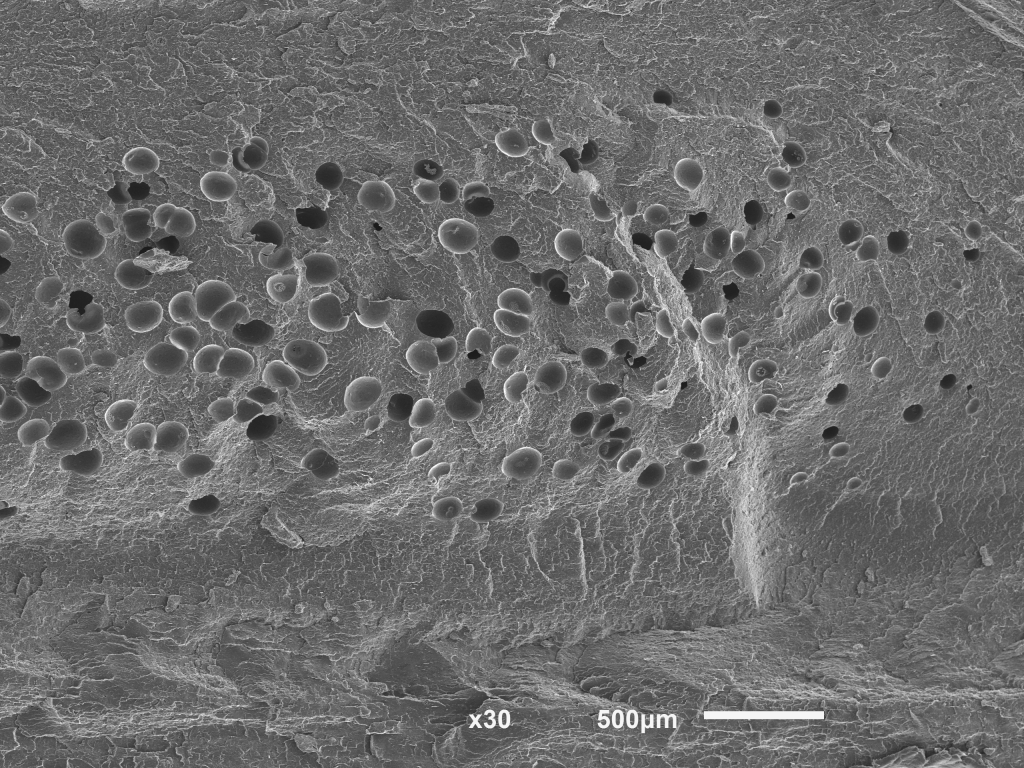

Another alternative is Foam Injection Molding (FIM), which involves incorporating a blowing agent (physical or chemical) into the molten polymer, resulting in parts with an internal cellular structure [7]. The introduction of blowing agents creates a microcellular structure within the part, reducing density and, consequently, weight to achieve specific mechanical properties [8]. PIEP, as a scientific and technological entity, has sought to leverage the development of its capabilities with a vision for a greener and more sustainable future. As part of the European VITAL project, under the Horizon Europe Framework Programme (HORIZON) [9], PIEP has led the study of developing microcellular foams using thermoplastic materials and bio-based blowing agents, with a special emphasis on the automotive and consumer (appliance) sectors. Projects like VITAL demonstrate how new technologies can be applied to optimize injection processes and product circularity. The use of recyclable or biobased materials, along with manufacturing technology, contributes to reducing waste compared to traditional injection solutions.

Despite the advantages of using technologies such as FIM, combining them allows for improved injection process control and optimized part quality. Gas Counter Pressure (GCP) is a complementary technology that can be applied particularly to parts with complex geometries or stringent requirements [10]. In this specific case, applying internal pressure to the cavity helps stabilize the part during injection to address issues such as filling failures and enables more uniform parts [11]. Thus, the combination of these two technologies translates into a holistic process approach, enabling higher-quality parts (surface finish, structural uniformity, and strength), opening up a new range of applications for the plastics industry. As part of Activity 3 of the internal Polarise project, part of the development of new skills and capabilities, PIEP intends to combine FIM and GCP. Exploring the synergies between FIM and GCP opens up new possibilities for product design and expands the introduction of new functionalities, providing a new opportunity for the thermoplastics industry.

Regarding different plastic part production technologies, multicomponent injection is also identified as a trend. This technology enables the multimaterial and multifunctional production of parts, combining the properties of different materials in a single production step, either through multimaterial injection or by integrating inserts or films into the mold cavity. This increases design flexibility and reduces, or even eliminates, post-assembly, adhesion, or welding processes [6].

The advancement of injection systems can therefore prove to be a strategy for the competitiveness of mold and plastics companies. However, despite the advantages associated with these technologies, companies in the industry face several challenges in adopting them, including high investment in infrastructure and qualified professional training, as well as the modernization of production processes and/or cultural adaptation within companies. Thus, collaboration between innovation centers like PIEP, which has been acquiring expertise in this area, and industry can accelerate the implementation of new technologies, the digitalization of processes, and the development of new materials, helping the sector align with global trends.

Authors:

Catarina I. Faria, Cátia Araújo e Sílvia Cruz

PIEP – Centre for Innovation in Polymer Engineering

Article originally published in Molde Magazine.

References

[1] TOYO Europe, “Innovation in Plastic Injection Molding: The Future is 100% Electric,” 17 Setembro 2024. [Online]. Available: https://toyo-europe.com/2024/09/17/innovation-in-plastic-injection-molding-the-future-is-100-electric/.

[2] Blocked. (2025). O futuro da indústria europeia rumo à sustentabilidade e foco no ser humano com a Indústria 5.0. Compete2030. Disponível em https://www.compete2030.gov.pt/comunicacao/o-futuro-da-industria-europeiarumo-a-sustentabilidade-e-foco-no-ser-humano-com-a-industria-5-0/

[3] Kuppe, F. (2023, outubro 26). Indústria 5.0: entenda tudo sobre a quinta revolução industrial. VC-X Solutions. Disponível em https://vcx.solutions/industria-5-0/

[4] Kistler. (2024). Manutenção preditiva e monitorização de moldes na moldagem por injeção. Kistler.com. Disponível em https://www.kistler.com/PT/pt/manutencao-preditiva-e-monitorizacao-de-moldes-na-moldagem-porinjecao/C00000573

[5] Pizoń, J., & Gola, A. (2023). Human–Machine Relationship—Perspective and Future Roadmap for Industry 5.0 Solutions. Machines, 11(2), 203. https://doi.org/10.3390/machines11020203

[6] Czepiel, M., Bańkosz, M., & Sobczak-Kupiec, A. (2023). Advanced Injection Molding Methods: Review. Materials, 16, 5802. https://doi.org/10.3390/ma16175802

[7] Knauf Industries Automotive. Foam Molding Technology. Knauf Automotive. Disponível em https://knaufautomotive.com/expertise/foam-molding/

[8] Heim, H.-P. (2015). Specialized Injection Molding Techniques. Em William Andrew Inprint of Elsevier Inc.

[9] Vital. (2022, setembro). Use Cases – Vital. Learning Factories for Circular Economy. Disponível em https://vital-project.eu/uses-cases/

[10] Lin, W., Hamamoto, Y., Hikima, Y., & Ohshima, M. (2023). Improvement of the surface quality of foam injection molded products from a material property perspective. Polymer Engineering & Science, 63(1), 44-54.

[11] Berry, M. (2011). 14 – Microcellular injection molding. Em Applied plastics engineering handbook (pp. 215-226). William Andrew Publishing.