The production of plastics has been increasing exponentially. In 2022, more than 300 million tons of plastics were produced, which represented an increase of 3% compared to the previous year. In that same year, 2022, the packaging industry used about 30% of the plastic produced, and polyethylene terephthalate (PET) was one of the most used, particularly in the beverage industry (OECD 2022). To reduce the extraction of virgin resources, and promote the circularity and sustainability of the packaging sector, the use of recycled PET (rPET) instead of using virgin PET (vPET) for the production of new packaging, e.g. water bottles, is proving to be an increasing interesting option. In this work, we show the advantages of using rPET through an environmental impact study that follows the international standards ISO14040-44.

The main objective of this study was to compare the environmental performance of two water bottles with different compositions and the same grammage. For this purpose, the Life Cycle Assessment (LCA) methodology was used. This methodology is an environmental management tool that allows assessing the environmental impacts of a product, service, or organisation and follows the ISO14040-44 standards. The LCA comprises four mandatory phases, namely, the definition of the objective and scope, the inventory analysis, the evaluation of the environmental impacts, and the interpretation of the results.

The definition of the objective and scope must contain the objectives of the study, the definition of the functional unit (FU), the breakdown of the system boundaries, the categories of environmental impact to be considered, and the evaluation method to be used. During the inventory analysis phase, all data that constitute the productive flowchart defined in the previous step must be collected, evaluated, and processed.

Finally, it is in the environmental impact assessment stage that an assessment of potential environmental impacts is carried out, taking into account the results of the previous stage, and in accordance with the method mentioned in the objective and scope definition stage. The interpretation of the results includes the critical analysis of the entire LCA process, and for this reason, this step should take place throughout the entire study, with a special focus on the detailed discussion of the results obtained. This step also includes a description of the main conclusions and the identification of the main limitations and recommendations of the study.

Definition of aim and scope

The main objective of this study was to compare the environmental performance of two water bottles with different compositions. The first bottle was produced with 100% vPET and the second with 50% vPET and 50% rPET. In order to compare the environmental impact of the two bottles, UF was defined as the production of a 0.5L water bottle.

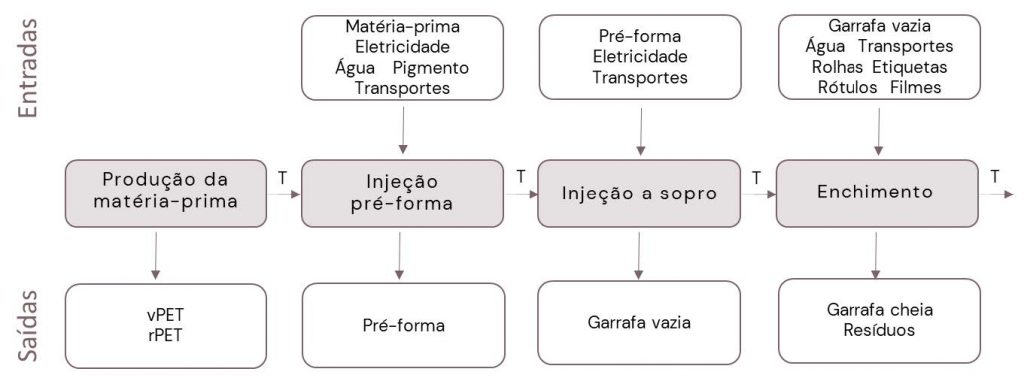

The LCA study follows a cradle-to-gate approach, and Figure 1 shows the considered system boundaries.

Figura 1. System boundaries.

Inventory analysis

For this study, SimaPro (version 9.4.0.1) was used as analysis software. The primary data relating to the production of raw materials were provided by the company Ecoibéria and the data relating to the production of the water bottle were provided by the company Logoplaste. When primary data were not available, Ecoinvent (version 3.7.1.) was used as the main secondary database. All data were transformed to the UF defined by mass allocation.

Assessment of environmental impacts

Environmental impacts were calculated according to the method used in the Environmental Product Declarations, and eight impact categories were considered: acidification, eutrophication, global warming, photochemical oxidation, abiotic depletion – elements, abiotic depletion – fossil fuels, water scarcity, and depletion of the ozone layer.

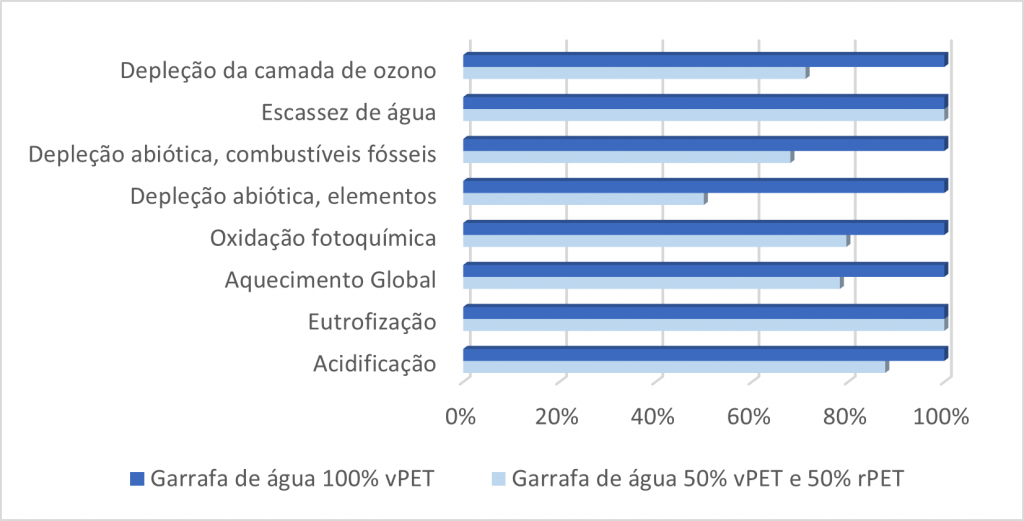

Figure 2 presents the results obtained for the environmental impact categories considered for the two bottles under study.

Figure 2. Comparison of the results obtained for the two bottles under study

The bottle produced with 100% virgin raw material has a superior environmental impact in all environmental impact categories, with the exception of water scarcity and eutrophication categories.

Results interpretation

The LCA results show that the production of bottles containing only virgin raw material generates higher environmental impacts compared to a bottle that incorporates recycled materials. This is essentially due to the fact that the production of vPET presents a more complex production process, and therefore predictably consumes more energy.

In conclusion, this study highlights the importance of incorporating recycled raw materials in the production of water bottles. These practices not only reduce the environmental impact of products, but also promote a more circular economy, and seem to guarantee greater and better long-term sustainability for the packaging sector.

Authors:

Inês Costa, PIEP | Catarina Silva, PIEP | Bruno Silva, PIEP | Pedro Santana, Logoplaste

Article originally published in InterPLAST Magazine.