The injection of materials loaded with magnetic particles, such as ferrite, is a manufacturing industry practice for the production of magnetic components. Generally, the injected materials are composed of a high magnetic load (55 – 65 vol%), resulting in a material of high viscosity, which makes the process difficult.

The injection of magnetic components is normally associated with the technique of powder injection moulding (PIM), with the moulding of the component first, followed by several post-processing stages, namely the sintering of the part, with total removal of the component plastic material (the polymer acting only as a binder so that the injection process is possible). After de-moulding, the part is subjected to high-intensity magnetic fields to promote magnetic orientation, making the part magnetic.

The Magnetized Gears project emerges as an alternative to the need for post-processing of magnetic components, promoting the magnetization of the part still in the mould, during the injection moulding process, allowing to eliminate steps in the process. The project is being developed in a consortium, within the scope of the Bosch Suppliers Club, integrating GLN Molds as the leading promoter, PIEP – Centre for Innovation in Polymer Engineering, GLN Plast, University of Minho, and CeNTI – Centre for Nanotechnology and Smart Materials.

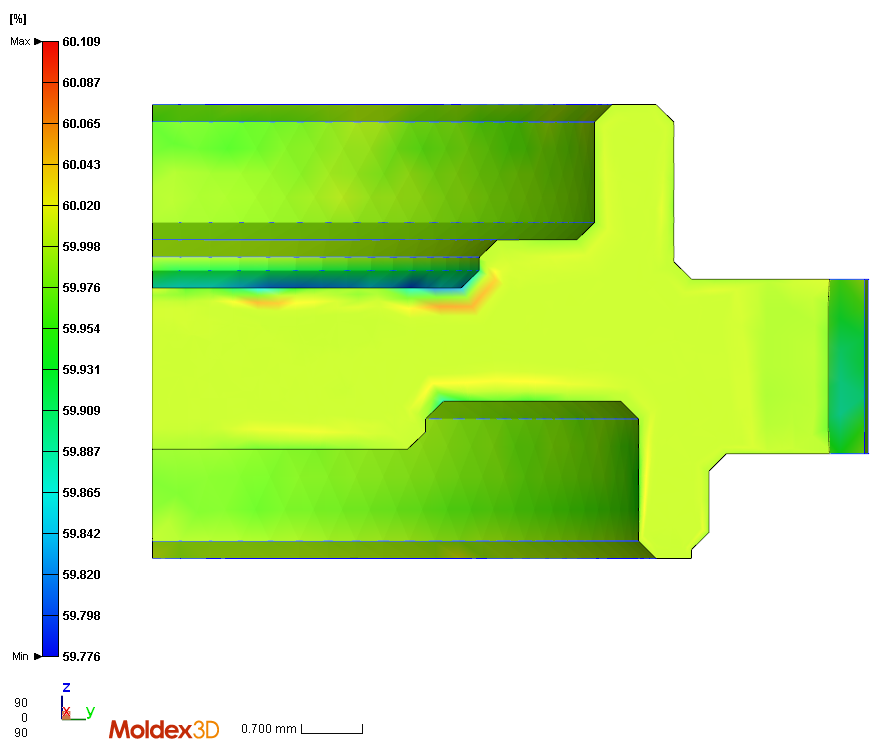

In this way, to help the development of the mould and production tool concept, studies are being carried out through numerical simulations using the PIM add-on of the Moldex3D software developed specifically for powder injection, capable of predicting the distribution of particles along the entire part, as seen in Figure 1, allowing to evaluate and prevent the existence of black lines (caused by the separation of phases between the polymer and the metallic powder), representing a point of weakness in the part.

Figure 1 –Cutaway view of the powder concentration distribution of the component under study.

In addition, numerical simulations help in the development of the production tool, making it possible to predict the expected injection pressures and the necessary closing force. With this study, it is also possible to simulate the existence of hot channels, which can help in the injection of highly charged components. In order to evaluate the structural integrity of the component, studies will also be carried out through numerical simulations, allowing to predict the mechanical behaviour of the resulting parts.

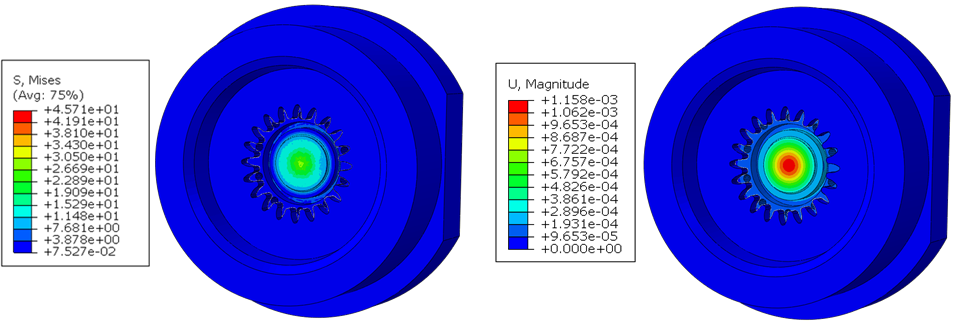

In addition to these simulations, numerical structural simulations were also carried out, using the Abaqus software, in order to analyze the mechanical performance of some of the mould components during the production process. These simulations aimed not only to optimize the thickness but also to select the most suitable material for the mould plate in contact with the molten material, in order to minimize its deformation. For this, the pressure distribution, obtained as a result of the simulations of the injection moulding process, was integrated into the structural simulations, changing the type of steel and plate thickness.

Through the analysis of stresses and strains obtained, it was possible to select the material and thickness configuration that guarantees the best performance.

Figure 2 – General view of the stresses and displacements observed in the analyzed plate.

Acknowledgments

Work carried out within the scope of the MAGNETIZED GEARS POCI-01-0247-FEDER-017684 project, financed by the European Regional Development Fund (ERDF) through the COMPETE 2020 Operational Program.

Authors:

Diana Dias, Research Engineer in the Advanced Manufacturing Processes – Polymers area of PIEP;

Lourenço Bastos, Research Engineer in the Product Design and Development area of PIEP;

Rita Marques, Project Manager in the Advanced Manufacturing Processes – Polymers area of PIEP;

Sílvia Cruz, Coordinator of the Advanced Manufacturing Processes – Polymers area of PIEP;

António Malaquias, Technical Manager, GLN Molds;

Miguel João, Technical Responsible, GLN.

Article originally published in Molde Magazine.